1025R Owners/Potential Owners – Beware!

The John Deere 1025R compact tractor, a reliable workhorse on many farms and properties across the United States. A trusted brand that touts its reliability. “Nothing runs like a Deere” – isn’t that what they say? Well, sometimes even the best known brands have products with design flaws. Let’s see how strong the John Deere reputation truly is. Here’s my story about a 2016 model year 1025R tractor with less than 200 hours on it suffering catastrophic engine failure due to a design flaw (or at the very least, a very questionable design, which was changed in newer models) with the air intake mount assembly in July of 2023.

I was moving some dirt around in the yard one day and had shut the tractor off after an hour of use and then started it back up a short time later to run it again. It made a funny noise on start up and then started running low and rough. I shut it down immediately. It took a few minutes to notice the hole in the top of the valve cover. Oh hell. I am not the original owner of this tractor, but with only 180-ish hours on it, I can’t imagine this would be a major engine problem. I was wrong.

The Diagnosis from the Mechanic

I had a very reputable local tractor mechanic pick up the tractor and haul it to his shop to take a look at the damage. He pulled the valve cover and was able to extract the cracked piece of valve cover that had fallen in, then used a probe to take a closer look. He echoed the findings of others, that this failure is due to a design flaw, and not misuse or neglect. He believes that the crack has been there for some time, based on the dirt and debris on the inside of the engine and the amount of damage that has been done. It didn’t happen in the 2-3 seconds that the engine started making noise and was shut off.

Come to find out this has happened to quite a few other owners too, prompting several discussions among tractor owners on forums like Green Tractor Talk (linked down at the bottom of this page) and several videos on Youtube (posted down at the bottom of this page). Turns out I’m not the only one having John Deere 1025R problems resulting in engine failure. Most of the situations I came across where someone experienced engine failure, JD took care of the owners and replaced the engines. I felt cautiously optimistic reading those accounts.

The 1025R Air Intake Mount Assembly Design Problem

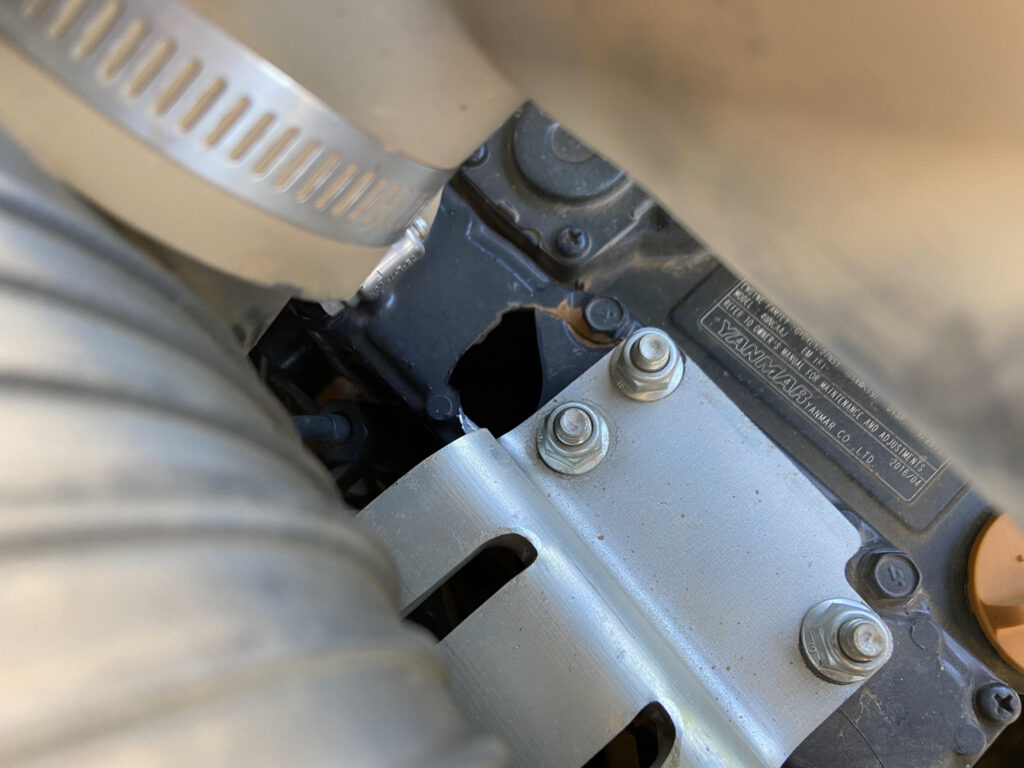

The engine itself isn’t the problem. It’s the fact that the air filter canister mount assembly is mounted to the valve cover. The air filter canister bracket is mounted to the valve cover by way of three threaded studs, which are molded into the valve cover casting, using a heavy steel bracket. The vibration of the engine puts a lot of stress on those studs, and by extension, the valve cover. The vibration ends up causing the valve cover to crack and break apart, in many cases dropping pieces of metal from the valve cover or the studs right into the motor, also allowing dirt and other debris into the combustion chamber through the cracks/holes. This can have devastating consequences, obviously, when that debris gets into the air inlet and the combustion chamber.

An early warning sign of trouble tends to be the air filter canister strap/bracket coming loose from the bracket. If you experience the strap rattling loose, be warned that an engine failure could soon follow. Your valve cover might already be cracked. In my case, the strap had fallen off at some point, maybe earlier that morning, without me even noticing. Quite a few 1025R owners have complained of their air filter canister rattling loose from the bracket strap.

John Deere started offering an air filter bracket relocation kit (Support Bracket Replacement Kit – LVU29618FIX) years ago. It’s been suggested that owners install this retrofit kit to avoid major engine damage like the failure I experienced. The newer model year 1025R tractors no longer have the air filter canister mounted to the valve cover.

John Deere’s Response To This Issue

John Deere has not made it widely known that a PIP exists for this. A PIP (JD’s Product Improvement Program) refers to a mechanical defect or design flaw that JD has acknowledged and is essentially a non-safety related recall. You can’t find it listed anywhere on their website, but one does exist. You have to check to see if your tractor’s serial number is affected. You can check their website or call an authorized JD service center and give them your serial number to see if your tractor is on the list. It’s been reported that they have replaced several engines because the failures caused by it. They are addressing it on a “as they fail” basis, and taking it case by case.

If you have a 1025R tractor made between 2015-2018, there’s a good chance it has (or had) the intake mounted to the valve cover. John Deere knows about this issue. They have been giving away air filter bracket “upgrade” kits for years, and have replaced many engines for customers due to this failure, and also moved the mounting point for the air filter canister to the firewall in later years. It’s been said that they are handling these failures on a case by case basis. If it happens to you, be sure to reach out to JD Global Support. The first step is always to let them know about it and give them the opportunity to help out.

The concerning thing with my situation is that I’m not the original owner who purchased the tractor brand new. This is for the second or third owner of a 7 year old tractor, albeit with very low usage. Not that this should matter when it’s a failure due to what can be best described as a serious design flaw that can result in a massively expensive engine failure, but it is usually a sticking point for warranty claims in just about any situation. Let’s hope that isn’t the case here, as that would be terribly disappointing – and a massive blow for me and my family. My fingers are crossed.

Next Steps

If John Deere doesn’t step up to replace the engine, I’ll be stuck paying for a replacement engine out of pocket. I did find some remanufactured options in the $5k-8k range. A brand new Yanmar 3TNV80F-NCJT diesel engine sells for somewhere in the $10k range, plus the cost to install it. That’s about as much as another used tractor. The cheaper path of replacing the broken parts isn’t a good option due to the damage to the cylinder walls. The life of the engine has likely been shortened.

I will be sure to update this website to share what John Deere’s response is and what I end up having to do to get this resolved. Having marketing background made it easy to build a quick website to use as a central source for this information. Not sure if it will help me or hurt me in this situation, but my goal is to bring more awareness to this issue to help other 1025R owners avoid an engine failure, or if they experience an engine failure, help educate them on what to do. The website didn’t cost me anything to build or host and hopefully it helps others who run into this down the road.

I’ll also collect more links to relevant videos and experiences from others across the internet to have it all posted in one central location here on the website. Hopefully we can get the word out to more 1025R owners to get their air filter bracket retrofit kit before they have to deal with a catastrophic failure.

Updates To My 1025R Engine Failure Experience

Contacted John Deere on July 28th

John Deere responded on August 3

Dropped the tractor off on August 8th

John Deere Rep Refuses to Help - August 15

Wait - JD Has Now Agreed to Help? August 16

Picked up the tractor today

Buyer Beware When Shopping for a Used John Deere 1025R Tractor

The engine failure issue in John Deere 1025R tractor models due to the air intake mount assembly mounting design can cost you almost as much as the tractor is worth to fix. If you own a 1025R that was made between 2015-2018, or are in the market for a used John Deere 1025R tractor, be sure that the air filter canister is NOT mounted to the valve cover, and is, in fact, mounted to the chassis. Be sure to closely inspect the valve cover near those three threaded studs on the top of the motor for cracks. If you see any, make sure you have a mechanic do an inspection of the internals with a probe to make sure there is no internal damage. Even if you don’t see any sign of cracks, I would advise getting the engine scoped/probed to be sure there is no internal damage from this issue. Engine rebuilds and/or replacement is NOT cheap for tractors. The cost for a remanufactured Yanmar engine is somewhere between $6,000 to $8,000. A brand new Yanmar engine is going to cost you over $10,000, not including labor.

You may want to consider a used Kubota instead.

Documented Discussions and Videos Surrounding This Design Flaw

Forum Discussion on GreenTractorTalk

Another Forum Discussion on GreenTractorTalk

Another Forum Discussion on GreenTractorTalk

Another Forum Discussion on GreenTractorTalk

https://www.youtube.com/watch?v=9OHQ7DkEmlM

I found dozens of others, just need time to add them. Stay tuned!

Links to Other Websites with Common 1025R Problems (and Solutions):

https://gardenaider.com/john-deere-1025r-problems/

https://tractorproblems.com/john-deere-1025r-problems/